Waxaa jira noocyo badan oo dahaadh bir ah. Dahaadhyo kala duwan waxay u baahan yihiin xoogagga tijaabada ee kala duwan ee tijaabada microhardness, xoogagga tijaabadana si aan kala sooc lahayn looma isticmaali karo. Taa beddelkeeda, tijaabooyinka waa in lagu sameeyaa iyadoo la raacayo qiimaha xoogga tijaabada ee heerarka ay ku taliyeen. Maanta, waxaan inta badan soo bandhigi doonnaa tijaabada adag ee micro Vickers ee dahaadh zinc ah ama dahaadh bir ah oo zinc-aluminium-magnesium ah oo lagu dabaqay birta.

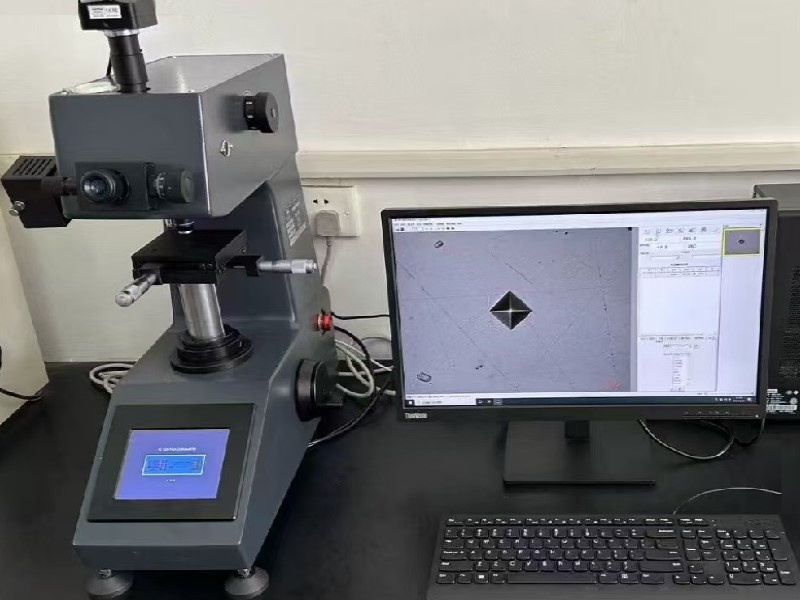

1. Diyaarinta muunado bir ah oo tayo sare leh oo dahaarka zinc ah (ama dahaarka aluminium-magnesium) waa tallaabada ugu horreysa ee tijaabinta dahaarka. Diyaarinta muunado dahaarka zinc waxay ku lug leedahay tallaabooyin badan, oo ay ku jiraan muunad qaadis, rakibid, iyo kahor shiidi iyo nadiifin. Ujeedada diyaarinta muunado noocaas ah waa in lagu shiido dusha sare ee shaqada oo loo rogo dusha siman oo siman oo u oggolaanaysa muuqaal cad oo ku saabsan godadka Vickers, taasoo sahlaysa cabbir sax ah oo cabbirrada godadka si loo helo qiimaha adkaanta.

2. Tijaabada adkaanta ee dahaarka zinc: maadaama dahaarka zinc uu yahay mid qaro weyn, tijaabooyinka adkaanta waxaa lagu samayn karaa awoodo tijaabo oo kala duwan. Isla muunadda, xoogga tijaabada ee la adeegsaday oo yar, cabbirka gelitaanka oo yar; taa beddelkeeda, xoogga tijaabada oo weyn, cabbirka gelitaanka oo weyn. Haddii dahaarka ku wareegsan gelitaanka uu muujiyo calaamado dildilaac ama isbeddel, waa in la doortaa xoog tijaabo oo yar. Habkan waa la soo celiyaa ilaa dahaarka ku wareegsan gelitaanka Vickers uu ahaado mid aan isbeddelin iyada oo aan isbeddelin - heerkan xoogga tijaabada ayaa ah kan ku habboon muunadda.

2.1 Dhumucyada dahaarka ee kala duwan waxay u dhigmaan heerarka xoogga tijaabada ee gaarka ah, taas oo muhiim u ah ka fogaanshaha qallooca natiijooyinka baaritaanka. Kuwa soo socdaa waa tixraac loogu talagalay xulashada xoogga tijaabada ee dahaarka caadiga ah (dahaadhka zinc, dahaadhka chromium), oo lagu dabaqi karo tijaabiyayaasha adag ee micro Vickers (HV):

| Nooca Dahaadhka | Dahaarka Dhumucda (μm) | Talo soo jeedin Xoogga Tijaabada (gf) | La xiriira Miisaanka HV | Taxaddarrada Muhiimka ah |

| Zinc Dahaadhka | 5 ~ 15 | 25 ~ 50 | HV0.025, HV0.05 | Dahaadhka Zinc waa mid jilicsan (badanaa HV50~150); xoog yar ayaa ka hortagaya in si xad dhaaf ah loo galo. |

| Zinc Dahaadhka | 15 ~ 50 | 50 ~ 100 | HV0.05, HV0.1 | Marka dhumucdu korodho, xoogga si habboon ayaa loo kordhin karaa si loo hubiyo in geesaha qalloocan ay cad yihiin. |

| Chromium Dahaadhka | 1 ~ 5 | 10 ~ 25 | HV0.01, HV0.025 | Chromium-ka adag (HV800 ~ 1200) wuxuu leeyahay adkeysi sare; xoog yar ayaa ka hortagaya dhaawaca gudaha. |

| Chromium Dahaadhka | 5 ~ 20 | 25 ~ 100 | HV0.025, HV0.1 | Marka dhumucdiisu tahay >10μm, HV0.1force waxay dheellitirtaa saxnaanta iyo hufnaanta. |

| Isku-dhafan Dahaarka | 5 | ≤25 | HV0.01, HV0.025 | Dahaarka sida dahaarka zinc-nickel iyo dahaarka chromium-nickel, si adag uga hortag in daloolku uu galo dahaarka. |

2.2 Arrimaha kale ee muhiimka ah ee saameeya

Marka laga soo tago dhumucda, labada arrimood ee soo socda ayaa si dheeraad ah wax uga beddeli doona xulashada xoogga tijaabada, waxayna u baahan doonaan inay ku qiimeeyaan xaaladaha dhabta ah:

Kala duwanaanshaha adkeysiga dahaadhka:

Dahaarka jilicsan (tusaale ahaan, dahaarka zinc, HV < 200): Haddii xoogga tijaabada uu aad u yar yahay, daloolada ayaa laga yaabaa inay noqdaan kuwo aan caddayn sababtoo ah isbeddelka balaastikada ee dahaarka. Waxaa lagu talinayaa inaad doorato xadka sare ee xadka lagu taliyay (sida., dhumucda 10 μm, dooro 50gf xoog tijaabo ah).

Dahaarka adag (tusaale ahaan, dahaarka chromium, HV > 800): Adkaanta sare waxay keentaa daloolo yaryar, sidaa darteed xoogga tijaabada waa inaanu aad u yareyn (sida, dhumucda 5 μm, dooro xoogga tijaabada 25gf) si looga hortago khaladka cabbirka ee geeska daloolinta inuu ka bato ±5%.

2.3 Shuruudaha Heerarka iyo Tilmaamaha

Warshado kala duwan waxay leeyihiin heerar cad. Tusaale ahaan:

Warshadaha baabuurta ayaa si caadi ah u qaata ISO 14577 (Tijaabada Qalliinka Qalabka), kaas oo u oggolaanaya hagaajinta qiimaha xoogga iyadoo loo eegayo dhumucda dahaarka;

Warshadaha guud waxay tilmaamayaan ASTM E384, kaas oo u baahan in leexashada leexashadu ay tahay ≤ 1/2 dhumucda dahaarka iyo ≥ 10 jeer radius-ka caarada leexashada (si looga fogaado saameynta caarada).

Gunaanadkii, xulashada xoogga tijaabada ee tijaabada adag ee micro-Vickers ee dahaarka birta ah waa inay raacaan macquulka ah "marka hore dhumucda, hagaajinta adkaanta, iyo dammaanadda caadiga ah":

Marka hore, go'aami xoogga tijaabada iyadoo lagu saleynayo dhumucda dahaarka (tixraac jadwalka kore);

Hagaaji qiimaha xoogga iyadoo loo eegayo adkaanta dahaarka (xullo xadka sare ee dahaarka jilicsan iyo xadka hoose ee dahaarka adag);

Ugu dambeyntii, la jaanqaad heerarka warshadaha (sida ISO 14577 iyo ASTM E384) si loo hubiyo ansaxnimada natiijooyinka baaritaanka.

Waqtiga boostada: Sebtembar-03-2025